Powders for MIM and AM: to each his own

In the introduction of this article, we’ve already discussed how different powder metallurgy technologies rely on vacuum furnaces for critical steps of their production process, mentioning Metal Injection Molding (MIM), Binder Jetting (BJT), Powder Bed Fusion (PBF) and Direct Energy Deposition (DED) additive manufacturing.

Even though these technologies may have some common applications and technological aspects, the powder employed on each of them has some peculiarities that differentiates it from the others.

Let’s find out what are the differences.

Additive Manufacturing

Powders for PBF and DED additive manufacturing applications are usually produced through gas atomization or plasma atomization; the first one is undoubtedly the most popular, while the second one is generally used for reactive materials.

Gas and plasma atomization processes in fact, allow to obtain powders with very high metallurgical quality, low impurity content and near perfect spherical shape.

Having a tight control on the metallurgical properties of the powder and on the oxygen and impurities content is in fact critical for aerospace and medical applications, industries that are one of the largest market for AM systems and have to refer to strict regulations regarding materials and mechanical properties of the parts.

Also, sphericity is very important for PBF processes to achieve a high relative density and improve the flowability of the powder, ensuring a uniform spreading on the build plate.

Plasma atomization, despite the generally higher production costs and lower productivity, delivers the highest purity powders with trueness in the spherical shape of the particles and minimal satellite content. It is usually the applied to the production of reactive materials, for example refractory metals (such as molybdenum, niobium, tantalum and tungsten) and for titanium alloys, whenever the highest purity is required (i.e. for the production of Ti-6Al4V Extra Low Interstitial).

Figure 3: Titanium AM parts produced using Electron Beam Melting (courtesy of Oak Ridge National Laboratory, licensed under CC BY 2.0)

Regarding the particles size, the distribution is usually finer (in the 20-45 µm range) for Laser-PBF compared to Electron beam-PBF (in the 45-100 µm range) and even larger for DED (50-150 µm).

In that respect, Binder Jetting represents an exception; the very nature of the BJT process, in fact, which relies on a powder-binder mixture to create green parts that are finally sintered, means that powders for Binder Jetting are much more similar to the ones adopted in Metal Injection Molding, which we’re going to discuss in the next paragraph.

Metal Injection Molding

The powders for MIM are usually produced through gas or water atomization. All the most common alloys employed in Metal Injection Molding can be produced using either of the two aforementioned methods, except for titanium alloys that cannot be manufactured via water atomization, for the same reasons discussed in the last paragraph.

As already mentioned, gas atomized powders have high levels of cleanliness and sphericity.

In comparison, water atomized powders usually have a higher oxygen content and more irregular shape but with lower production costs.

Even though spherical powder particles allow to obtain a better relative density, an irregular shaped powder gives some advantages for MIM applications, helping with shape retention of the part during debinding and sintering.

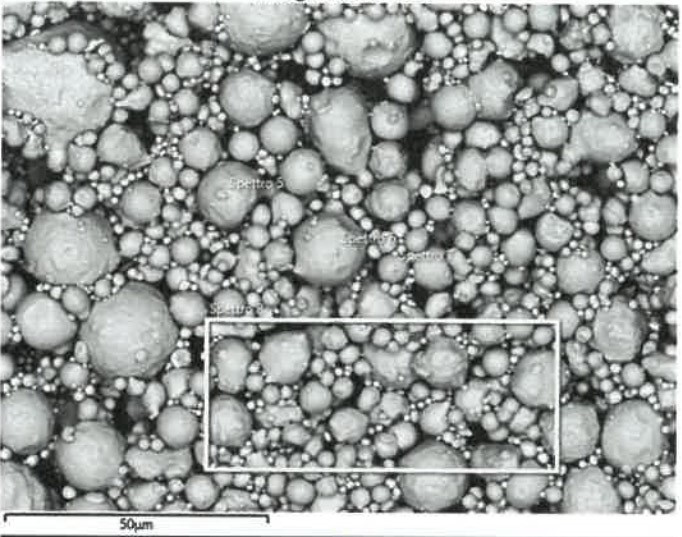

Figure 4: SEM Image of a MIM component before sintering showing the typical particle size distribution for powder employed in the MIM industry.

Finally, powders for MIM usually have particle sized in the 5-25 µm range, which is experimentally proved to be the range providing the best trade off between too fine particles, which will sinter better but load poorly into a binder system, and too coarse particles, which will sinter poorly.

In conclusion, a good knowledge of metal powders will allow to select the best product for the specific application and the most suitable process parameters.

Also, the outcome of heat treatments for powder metallurgy parts is strictly related to the powder properties; a suboptimal particle size distribution, for example, won’t allow sintered parts to reach their maximum density.

If you’re interested in the vacuum sintering of PM components, check out our “Ultimate guide to vacuum sintering” and our article on “Vacuum sintering of stainless steels: how to choose the right sintering atmosphere”.

For more information on heat treatments of additively manufactured parts, instead, have a look at our article on “Why heat treating metals after additive manufacturing?”.