In this article, I will talk about Additive Manufacturing and

in this case Selective Laser Melting (SLM). In particular, the

theme will focus on the role played by vacuum heat treatments in producing highly

reliable components, i.e. characterized by a better quality of the material and

an excellent fatigue resistance.

We will conclude by exposing the interesting experimental results obtained in

laboratory, thanks to a fruitful collaboration with the

University of Parma.

AM technology

Starting from a digital file and printing metal objects in 3 dimensions is no

longer a science fiction novel technology, but a reality possible with the

Additive Manufacturing.

Starting from a 3D design, it is possible to make metal components

with remarkable mechanical strength that can be used in various sectors, from medical

to aerospace. Thanks to Selective Laser Melting (SLM),

the creation takes place using a powder bed and a high power laser source, all controlled

in real time by a computer.

The role of the vacuum furnace in additive manufacturing

One of the tools to ensure that with this technology functional components can

be realized for the concrete application are the vacuum furnaces;

indeed, after the additive manufacturing process, heat treatments

or surface mechanical finish treatments are fundamental.

Vacuum furnaces are therefore essential for post-process treatments and are suitable

for processing a variety of materials, such as stainless steels,

titanium superalloys, cobalt-chromium alloys and

nickel superalloys.

Why heat treating under vacuum?

The products made by 3D printing are near-net-shape, in the

sense that selective melting (SLM) yields a lower production rate than other conventional

technologies, making it possible to obtain a more detailed component with more complex

forms, with less material, which otherwise would be almost impossible to obtain.

The passage inside a vacuum furnace therefore appears to be of considerable importance,

as it is characterized by the absence of oxygen and special diffusion pumps which,

through precise temperature control, determine the desired vacuum conditions. The

lack of oxygen is fundamental for medical and aerospace applications, for which

oxide contamination must absolutely be avoided.

The vacuum heat treatments are different depending on the considered additive

technologies.

Specifically, the heat treatments of

debiding and sintering are

indicated for the technologies of Fused Filament Fabrication (FFF) and

of Binder Jetting,

while the treatments of stress relieving and/or solubilization

are carried out for the Selective Laser Melting (SLM) technology.

What makes a vacuum furnace ideal for treating near-net-shape products?

Continue reading and find out which are the 3 critical points to keep under control

in Selective Laser Melting.

Did you like this article up to here?

Before you continue, follow us on our LinkedIn page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

Additive manufacturing: laboratory results

In order to make the research on heat treatments more effective, we have set

up a special laboratory in which we have installed an all‑metal vacuum furnace

H3 and with which various types of tests have been carried out (hardening,

stress relieving, annealing, sintering, tempering,

etc.). Moreover, in the same laboratory a machine for the deposition of PVD coatings

with rotating cathodes has been positioned for a better surface finish of the samples

made using additive technologies.

The results obtained from the analysis carried out in the TAV laboratory were

aimed at:

- obtain a know-how in vacuum treatments and in the production of the relevant

furnaces to support companies, universities and research centers;

- take part in partnerships and research projects for the development of these

and other emerging technologies;

- prepare and publish scientific information texts.

The Collaboration with the University of Parma

One of the most recent activities developed by TAV VACUUM FURNACES is a collaboration

with the University of Parma

on the topic of optimal fatigue resistance of specimens made with SLM technology.

Fatigue is one of the most significant and complex parameters of industrial components;

in the aeronautical field, in fact, fatigue is counted as the cause of a high percentage

of breakages and it is for this reason that the focus of the study has focused on

it in particular.

The objectives of the collaboration were as follows:

- determining the behavior of fatigue resistance at high rpm on samples made

with AM technology;

- evaluate the effects of vacuum heat treatment on the fatigue strength of

SLM components;

- consider the impact of anisotropy of SLM components on fatigue resistance.

Fatigue performance of the components

That of Additive Manufacturing SLM is a process that presents three fundamental

critical issues, which concern:

- the quality of the material in terms of metallographic microstructures;

- surface roughness;

- the process residues present on the final component.

To obtain the experimental results that I will show you shortly, specimens were

used in alpha/beta titanium superalloy (Ti-6Al-4V). The choice

of this material was not accidental; it is a particularly light alloy, but resistant

to corrosion and high temperatures. These characteristics make it the most suitable

material for automotive, aerospace and biomedical engineering applications.

The research was carried out through the use of standard samples with different

mechanical finishes and at a later stage, these were subjected to rotary bending

tests for measuring fatigue resistance.

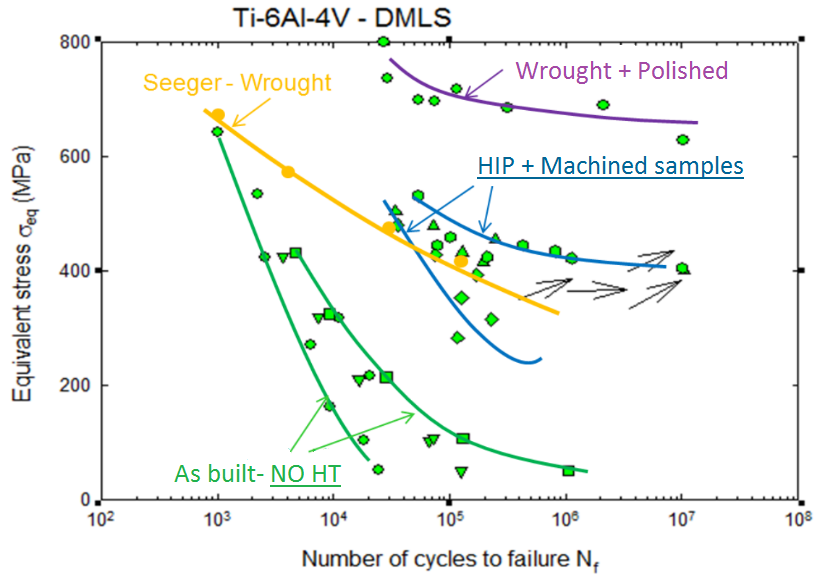

Looking at the graph below, you can see that as the mechanical surface finish

increases, the fatigue resistance is also increased.

The two curves of the same color indicate that, with the same surface finish,

the two standard samples were increased in two different orthogonal directions with

respect to the plane on which the piece was built; the specimens therefore assumed

a different behavior depending on the direction of growth and this demonstrates

the relevance of the intrinsic anisotropic characteristic of the SLM technology.

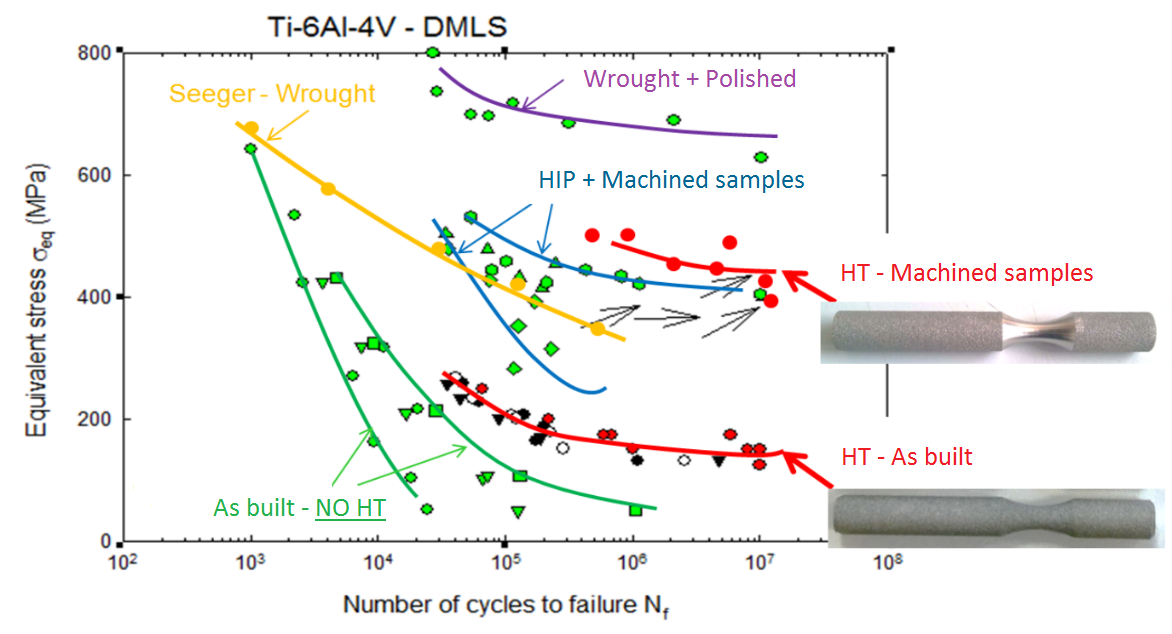

In the second graph, you can see the effect of heat treatment on some samples,

indicated with red color curves. The trend of the curves shows that heat-treated

specimens exhibit better behavior in terms of fatigue performance, compared

to untreated ones.

Conclusions

Additive Manufacturing it is undeniably the emerging technology

in the field of engineering. The realization of components destined for strategic

sectors requires processes and machinery that make a finished product and it is

able to withstand the stresses deriving from the application in the field.

We have shown in the laboratory that vacuum furnaces represent a highly functional

tool for performing post-heat treatment processes at Selective Laser Melting:

the passage inside a vacuum furnace determines improvements in the microstructure

of the material in terms of detensioning, isotropic behavior and surface roughness.

If you are interested in learning more, I invite you to read the article by Prof.

Nicoletto of the Department of Industrial Engineering of the University of Parma:

Metal additive manufacturing

and vacuum heat treatments.

Do you like this blog?

For us your opinion matters, so we would be very pleased if you could write a review about us or our blog.