Before we examine just how useful vacuum brazing furnaces can be for car, truck

and motorcycle manufacturers, it is probably best to define exactly what this process

is for those who are not yet experts in this particular field.

Essentially,

brazing makes two metals bond with one another by applying a metallic filler. For

a good join to be made, this filler must possess a lower melting point than the

temperature than either of the two metals that are being joined would liquefy at.

When the filler is melted it must make physical contact with either side of the

join, forming a solid bond once it solidifies.

Obtaining a Strong Joint

In most cases, this is achieved by vehicle manufacturers by using the right sort

of filler metal for the particular join. In fact, there are plenty of options to

choose between - the filler could come in the form of a wire, a thin plate or even

a paste, for instance. It simply depends on the sort of application that the process

is being conducted for.

Of course, in order to achieve a high-quality bond - both for physical properties

of stress resistance and the ability to withstand corrosion - it is preferable

to have a highly controlled environment. This is because grime and even

airborne particles could contaminate the brazing process, something that the leading

players in the automotive sector wish to avoid at all costs.

This is where vacuum brazing comes in which is what we will discuss next.

Later, you will also discover how the leading vacuum brazing furnace technologies

work to ensure that the stringent quality control measures required of all metal

joins in the automotive sector are maintained.

Automotive Heat Treatments and Vacuum Furnace Technology

For an effective brazing heat treatment, the cleanest level of atmosphere should

be obtained which, for a highly precise engineering sector like the automotive industry,

really means generating a vacuum.

Because a vacuum furnace can minimise

the contamination of any impurities in the local environment to virtually zero,

the joined metal will be high mechanically resistant and long-lasting. This is especially

important for car makers where complicated parts must be connected to one another,

often with non-standard shapes.

Given that the automotive sector also relies on many joining points in a relatively

small space, vacuum furnace brazing also makes a great deal of sense. As such, the

industry will often use this heat treatments for applications such as water heat

exchangers joints. In the automotive sector, the use of aluminium as a principle

element for top-notch heat exchangers is becoming ever more popular.

Both

AA 3xxx and 4xxx aluminium alloys are commonly used materials in

the sector, for example. The main reason why these particular alloys are so useful

is that they afford a very low specific weight whilst still offering a high level

of thermal conductivity.

As outlined above, one of the cleanest environments for precision brazing

applications in the automotive sector is a vacuum. Therefore, readers with

an interest in automotive heat treatments and aluminium alloys, in particular, should

read on for a more in-depth analysis of the individual properties of semi-automatic

vacuum brazing furnaces which makes them so suited to the common applications

required of the automotive industry.

Did you like this article up to here?

Before you continue, follow us on our LinkedIn page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

Three Station Design for Vacuum Brazing Furnaces

The brazing furnaces made by TAV VACUUM FURNACES are ideal for the automotive

industry because their design is composed of three distinct stations. These are:

- A precision heating furnace

- A functional loading station

- A useful cooling station

To understand how these three stations function in ways which suit the vehicle

manufacturing sector, we will deal with each in turn.

Heating Furnace Technology

Furnace Vessels

The vessel is an essential part of a furnace’s world-class heating process

technology. This is because it makes a separate enclosure that isolates the internal

section of the furnace.

Essentially, it contains the hot chamber and prevents

the outside environment from interfering with the brazing process.

In terms

of its design, the furnace has an extended horizontal axis, an elliptical shape,

ideal for many automotive heat treatments.

There are a pair

of flat doors, one at the front and one at the rear, for ease of access. These can

be operated manually. In addition, TAV's vacuum brazing vessels have a front door

which operates automatically.

This is used for both loading and unloading the

vessel.

Hot Chambers

The hot chamber in a heating furnace is constructed from high-quality panels

made of stainless steel with resistors fashioned from nickel-chrome. The hot chamber comes with dimensions of 180cm by 45cm by 365cm and inside there are in excess of 20 independently

controlled heating zones.

Together, these make the hot chamber extremely controllable

with the ability to fine tune the temperature, just as required.

In fact, maintaining the uniformity of heat in the chamber is extremely

important for automotive vacuum furnace applications.

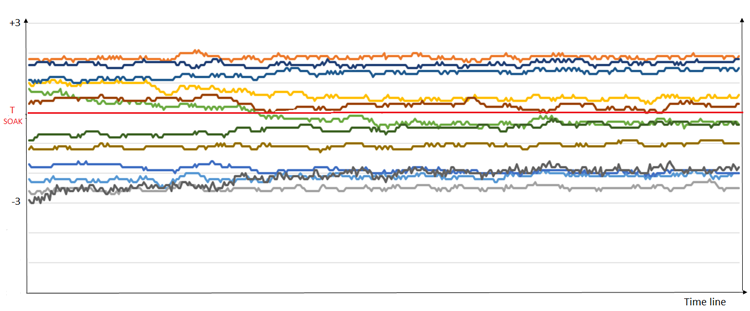

Therefore, vacuum

furnaces should never vary by more than three degrees from the set temperature in

either direction. As this survey graph adequately demonstrates, the desired ±3°C temperature uniformity is achieved even with repeated use.

TUS example at a specific temperature with 12 TLC

Vacuum Systems

The final part of the vacuum furnace technology that should be discussed is the

vacuum system itself.

After all, it is this which allows the hot chamber and

the furnace vessel to do such a good job.

There are three pumping groups to

ensure a good vacuum is maintained while the furnace is in use.

Two groups are

made up of pair of rotary piston pumps. One is a positive displacement

lobe pump, known as a Roots pump, and the other is an oil diffusion pump.

The

third pumping group comprises a conventional mechanical pump, another Roots

pump as well as a cryo-trap. These are deployed to remove unwanted humidity

in addition to any impurities that might be released into the chamber during a treatment.

Without a load, the vacuum level that can be achieved with this vacuum system

is an astonishing 10-6 mbar (range).

Loading and Cooling Stations

The other two stations needed to conduct vacuum brazing in a precise manner are

loading and cooling stations.

Expertly designed steel shelves fixtures hold the required parts. They help to

keep them together along with the filler metal that will be used for the brazing

process itself.

Any load from 900 kilos up to 2,200 kilos can be processed simultaneously

with these loading stations.

When a brazing heat treatment has been completed, the load is automatically transferred

to a cooling station chamber. This is where the processed metal joins can be cooled

down in a controlled manner with recirculated air.

Key Heat Treatment Considerations

Although you will, by now, have gained some useful insights into expert

automotive heat treatments in vacuum environments, it is also worth considering

a few other factors.

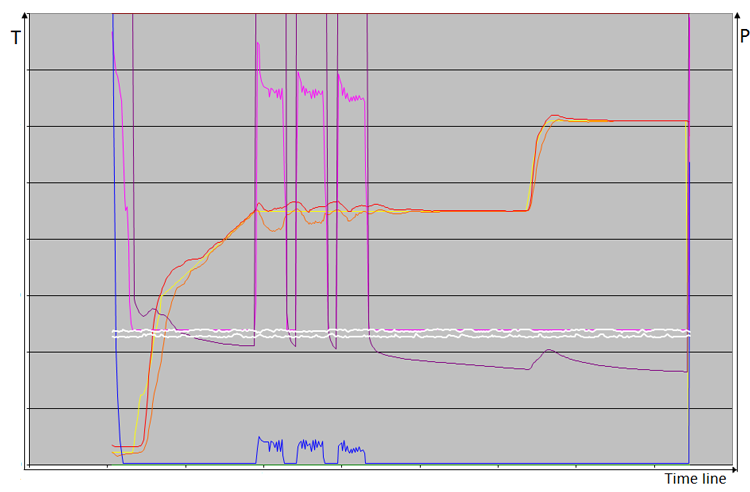

For example, prior to the required brazing temperature

being reached, it is essential that the load should be kept at a lower temperature

until all of the working oil plates from the heat exchangers has been removed.

Typical brazing cycle. Line yellow is the setpoint, line

orange is the temperature TC, line blue is the high vacuum level and purple line

is the partial pressure in mbar detected.

Another factor comes after the brazing process itself.

After the brazing

step, the furnace reaches high nitrogen static partial pressure starting the cooling

phase, as indicated in the following graph. After completion, furnace's front door

opens automatically and loading station can be removed from within.

Conclusion

There are many applications that the automotive sector can put vacuum brazing

technology to. However, it is only reliable when high-performance vacuum furnaces

are used.

If you want more information leave a message here below and turn to

our expertise.

Do you need more info?

Write to our engineers and discover all the vacuum furnace applications for the automotive sector.