Additive manufacturing using metals and alloys

The term Additive Manufacturing (AM) refers to the process that allows the joining

of materials, using technologies that are also very different from each other and

according to a layer upon layer method (additive manufacturing), to make objects

(e.g. component parts, semi-finished products or finished products) starting from

3D digital models, as opposed to traditional production methods

(turning, milling, etc.) which instead require subtraction from a solid (Subtractive

Manufacturing).

The AM techniques require that the three-dimensional object is created starting

from computerized 3D models and using different materials including metal, plastic,

ceramic, composite or biological ones.

In the additive manufacturing of metals and alloys, these are used in the form

of powders or wires.

The raw material is selectively melted by a focused heat source and then consolidated

during cooling, to finally form the designed piece.

The processes of AM that more than others employ metallic materials, are those included

in the categories Powder Bed Fusion (PBF) and Direct Energy Deposition

(DED), in particular: Selective Laser Melting (SLM), Direct Metal Laser

Sintering (DMLS), Electron Beam Melting (EBM), Laser Engineered

Net Shaping (LENS), Direct Metal Deposition (DMD).

Among the commercial metallic materials currently available to be processed through

AM processes there are: pure Ti, Ti-6Al-4V alloy, some stainless steels such as

316L, and PH 17-4, maraging steel 18Ni300, the AlSi10Mg alloy, CoCrMo alloys and

Ni-Cr Inconel 625 superalloy.

To the list just proposed, the materials shown in Table 1 can be added.

| Titanium |

Aluminum |

Tool steels |

Superalloys |

Stainless steels |

Refractory |

| ELI Ti |

6061 |

H13 |

IN718 |

316 |

MoRe |

| TiAl |

|

Cermets |

Stellite |

420 |

Ta-W |

| CP Ti |

|

|

|

347 |

Alumina |

Table 1 - Metallic materials for AM

Precious metals, such as gold, silver and platinum have been indirectly treated,

that is molds for the lost-wax casting technique have been made using 3D printing,

in which the cited materials have been cast; the same materials are also used directly,

for example, with the SLM technique.

Among the metallic materials just listed, stainless steels are those that find application

in the greatest number of sectors: aerospace, medical,

energetic, automotive, naval,

etc.

The mechanical characteristics (resistance to static and dynamic stresses) and

the density of the pieces produced by additive manufacturing with these materials

have long been studied and are currently very high, that is, similar if not higher

than those of traditionally manufactured parts. Their resistance to corrosion is

less well known and investigated. This property is fundamental in specific applications,

such as, for example, those in the nautical sector.

Study of the corrosion resistance of metal parts made with AM: characteristics

of the studied materials and the analysis carried out

To investigate the corrosion behavior of stainless steel parts produced

by additive manufacturing, the Metallurgy section of the Department of

Chemistry and Industrial Chemistry (DCCI) of the University of Genoa in collaboration

with TAV VACUUM FURNACES, the Saiem Srl company of Cairo Montenotte (Savona) and

the CNR-ICMATE of Padua started the study of 316L steel samples made using the SLM

technique (Selective Laser Melting). Specifically, Saiem Srl has

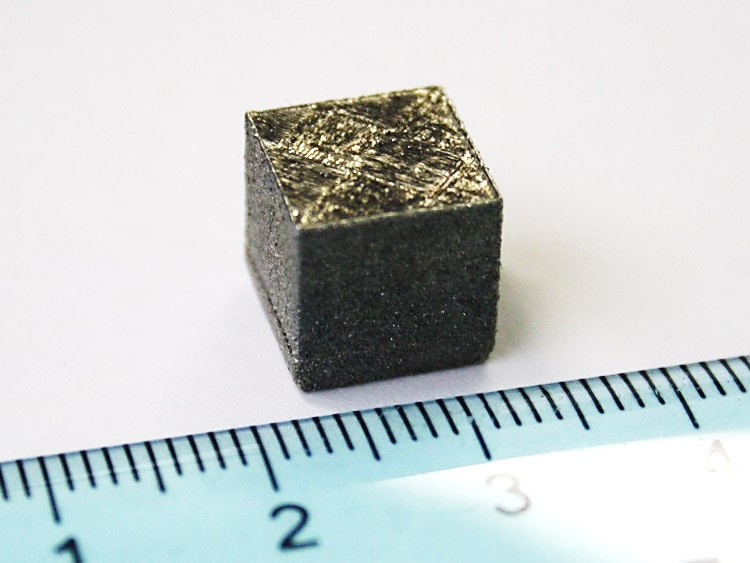

produced a series of samples, of dimensions 1x1x1 cm3 (Figure 1) using

the TRUMPF Tru Print 1000 system and pre-bonded powders specially designed and tested

for use with the cited 3D printer.

As can be seen from the image (Figure 1), the pieces produced have surfaces with

different morphology and roughness.

Figure 1 - Cube 1x1x1 cm3 realized through

SLM

The final made parts have the composition indicated in Table 2, corresponding

to that of 316L austenitic stainless steel (X2 CrNiMo17-2-2, DIN EN 10088-1).

| Fe |

Cr |

Ni |

Mo |

Mn |

Si |

C |

N |

P |

S |

| Bul. |

16.5-18.5 |

10.0-13.0 |

2.00-2.50 |

<2.00 |

<1.00 |

<0.030 |

<0.10 |

<0.045 |

<0.015 |

Table 2 - Chemical composition of the molded parts (wt.%)

For the study of microstructure and corrosion resistance, the samples were then

subjected to metallographic and electrochemical characterization, respectively,

the first through Scanning Electron Microscopy (SEM), Fluorescence

X-ray Spectroscopy and Optical Bright Field Microscopy

(LOM-BF), the second by means of Potentiometric Analysis is

Electrochemical Impedance Spectroscopy (EIS).

Part of the samples produced by Saiem Srl was further treated, that is, some cubes

were coated with TiN-based coating (both at TAV VACUUM FURNACES and at the CNR ICMATE

of Pd), others based on AlTiN (at the CNR) , others were subjected to a heat cycle.

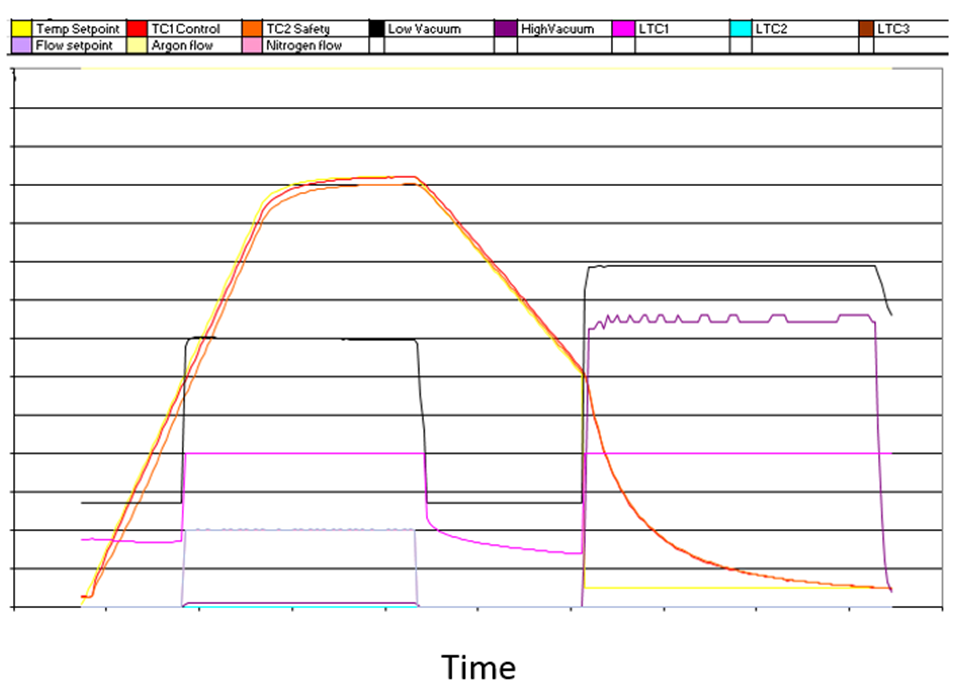

The applied heat cycle, Figure 2, was performed at TAV VACUUM FURNACES.

Figure 3. Applied heat cycle

Both the microstructural aspects and the corrosion behavior of these samples

(those coated with coatings of different composition or subjected to heat treatment)

were evaluated. In particular, it was decided to verify whether the treatments applied

resulted in an improvement or deterioration of the corrosion resistance of the studied

samples.

Did you like this article up to here?

Before you continue, follow us on our Twitter page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

Laboratory results

Metallographic characteristics of the samples

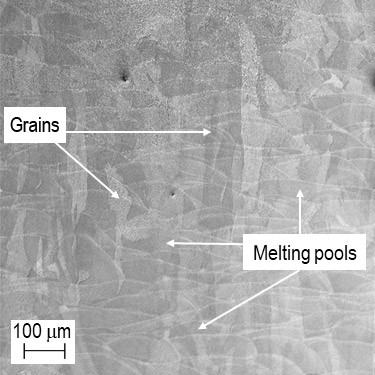

The microstructural analysis concerned the longitudinal and transverse sections

of the "as they are" samples and the longitudinal sections of the samples

subjected to heat treatment.

The study of SEM and LOM-BF micrographs allowed to find a high density

of the produced pieces. There are few visible pores and characterized by

spherical shapes with a diameter between 1 and 10 mm (attributable to gases trapped

in the material during the production of the piece), or by irregular shapes (these

pores are due to the printing process itself and can have dimensions from macroscopic

to sub-micrometric).

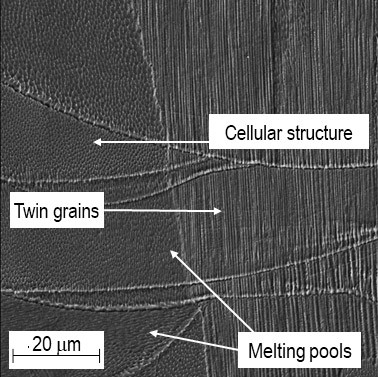

The microstructure of the samples, investigated after attack with aqua regia

(HNO3:HCl:H2O 3:10:10 in volume), highlighted the presence of elongated and oriented

grains along the direction of the piece construction, corresponding to the direction

of the heat progress (Figure 4), single melting pools, with dimensions

of about 100 mm along the horizontal axis, twin grains and a cellular structure

in which the intracellular spaces are less than 1 mm (Figure 5).

The microstructure just described, especially the observed cellular structure,

is typical of metal parts produced by additive manufacturing techniques,

characterized by solidification processes with high cooling speeds and a high degree

of subcooling.

Figure 4 - SEM-SE: Microstructure of the sample

along the longitudinal section after attack with aqua regia (magnification

200x).

Figure 5 - SEM-SE: Microstructure of the sample

along the longitudinal section after attack with aqua regia (magnification

8500x).

In the case of samples subjected to heat treatment, the microstructure is different

from that found when observing the samples as printed, since it is characterized

by large grains and in which details such as melting pools, twin grains and the cellular structure, are no longer appreciable.

Electrochemical characteristics of the samples

The electrochemical measurements concerned the lateral and lower surfaces of

the sample produced by SLM in order to verify its corrosion behavior in relation

to a commercially used reference sample of 316L.

Electrochemical polarization tests

These measurements have shown a variable passive behavior, typical of a material

characterized by a surface oxidation film that greatly limits the corrosion kinetics

by acting on the anodic semi-reaction.

Comparing the sample obtained by SLM with a commercial 316L sample, minor pass intervals

can be noted for all exposed faces, that is the lower and lateral faces, with higher

corrosion current densities for the lateral face.

The major critical issues, found on the lateral surface, can be correlated to its

morphology and to the number and distribution of the porosities that determine additional

interface phenomena, to be further investigated.

Work continued with the assessment of the corrosion behavior of the "as is" side

face and of the same face subjected to various surface treatments and heat treatment.

Measurements showed that surface treatments resulted in greater protection of the

sample. In particular, among the treatments applied, the one that provided

the best protection was the one based on TiN deposited at TAV VACUUM FURNACES.

Electrochemical impedance spectroscopy (EIS)

Representing the massive sample, the lower surface of the sample printed using

SLM was considered, compared with a reference sample of AISI 316L. The EIS measured

for the lower surface was comparable to that obtained from the reference sample,

with a slight imbalance towards a better corrosion behavior on the part of the printed

sample.

The similarity between the results obtained is attributable to the comparable surface

finish, obtained in both cases by polishing with abrasive papers.

As regards the samples characterized by different surface morphology and subjected

to further treatments, the maximum resistance values were found for the sample coated

with TiN at TAV VACUUM FURNACES.

The best corrosion behavior is attributable to the nature of the applied layer and

to the best covering of the surface.

Conclusions

The analysis carried out has highlighted critical issues for the sample obtained

by SLM in relation to the type of the exposed surface.

The application of coating and the heat treatment

allowed to obtain good results from the point of view of the corrosion resistance.

This study project was a collaboration of

University of Genoa: P. Piccardo,

V. Bongiorno, R. Spotorno, G. Ghiara

SAIEM Srl: F. Fraternale, A. Ghiglia

TAV VACUUM FURNACES SPA: A. Fiorese

ICMATE-CNR: S. Battiston,

F. Montagner

Did you like the article?

Subscribe to our Telegram channel and stay up to date on most advanced technologies for heat treatments.

Don't you have Telegram?

If you do not have Telegram yet, use one of the following buttons to install it: