Additive Manufacturing means any technology capable of obtaining

a final component starting from a 3D CAD file and adding material layer by layer.

At a theoretical level, Additive Manufacturing only coincides with the 3D part construction

phase. In reality, in order to fully understand this technology, a series of other

preprinting and postprinting activities must be considered, which constitute the

entire supply chain of Additive Manufacturing.

In this article we will analyze the activities that precede and follow 3D printing,

paying particular attention to the requirements of the materials and the processes

necessary to obtain a high quality production.

In the next chapter we will discover how important the production of print material

is in order to avoid defects in the components.

The preprinting phase

If we limit the field of Additive Manufacturing to the single and more widespread

powder bed technology

Selective Laser

Melting (SLM), during the entire supply chain it is essential to take care of

the atmosphere that surrounds the material in all its production steps. For example,

considering the production of powders as a preprinting phase, it is necessary to

pay a lot of attention to how they are produced. If the powders were obtained through

an atomization process in an unsuitable atmosphere, we could find, in the printing

phase, oxidized powders, which could be particularly difficult to melt or could

melt generating defects inside the material of the molded component.

Assuming that the starting point of the powders is optimal, that is that the

powders have been produced correctly in terms of geometry and absence of oxides,

even during the process of 3D printing it is essential to control

the atmosphere inside the accretion chamber. This is easily understood since

3D SLM printing can be compared to a continuous welding process,

in which the fused pool must be continuously protected by inert gas. Despite the

inertization of the interface between the molten pool and the chamber environment,

small residues of oxygen or slight impurities contained in the gas, not perfectly

pure, can result in unwanted inclusions within the final piece, with consequent

unacceptable colors and deterioration mechanical performance in a future use.

Also the postprinting phase is important to optimize the mechanical properties

of the components. Read on to see the interesting results we've achieved in

the lab, using vacuum heat treatments.

Did you like this article up to here?

Before you continue, follow us on our LinkedIn page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

The postprinting phase

After 3D printing, most of the materials that can be printed with SLM technology

always need a heat treatment. This heat treatment can be de-tensioning

(to release most of the internal tensions accumulated in the material during the

printing phase) or of another type (to try to optimize the mechanical properties

of the component according to its specific application).

Usually these treatments are carried out in air or in controlled atmosphere.

In reality, TAV VACUUM FURNACES has experimented in its internal laboratory (figures

1 and 2) that on specific components and materials, such as stainless steel

(figures 3 and 4), titanium superalloys (figures 5, 6, 7 and 8),

superalloys of nickel and CoCr alloys, the use

of vacuum is required.

In the case of titanium, even a low vacuum level around 10^-3 mbar is not sufficient.

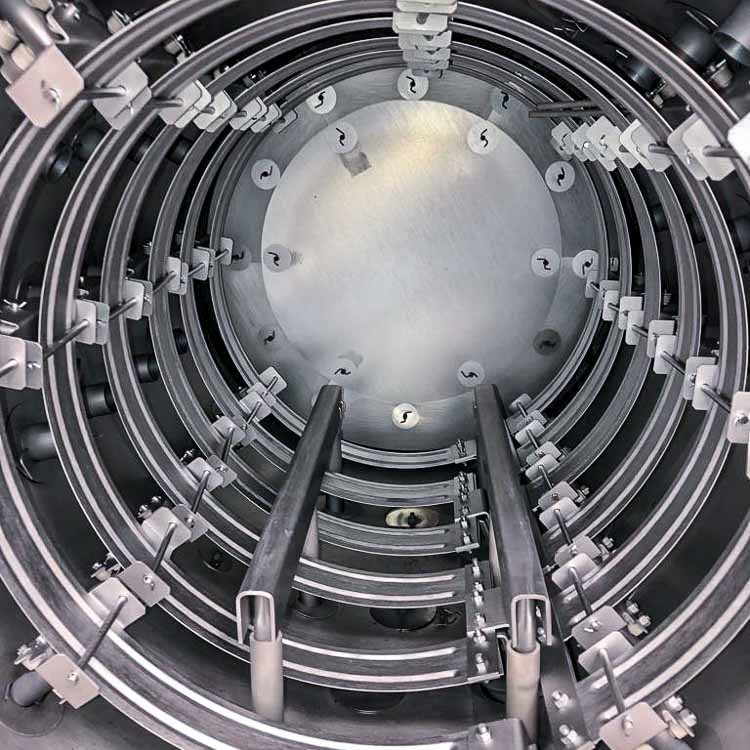

Figure 1: TheTAV VACUUM FURNACES R&D Laboratory.

Figure 2: Detail of a TAV furnace hot chamber in molybdenum.

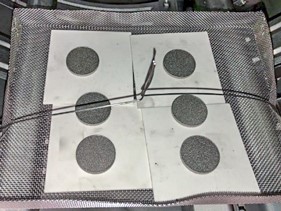

Figure 3: SLM samples in 316 L steel before heat

treatment. The samples were printed by SAIEM and analyzed by the University

of Genoa (DCCI).

Figure 4: SLM samples in 316 L steel after heat

treatment. The samples were printed by SAIEM.

Figure 5: SLM samples in Ti6Al4V before heat treatment

printed at the CNR, Institute of Chemistry of Condensed Materials and Energy

Technologies, CNR ICMATE, Lecco site.

Figure 6: SLM samples in Ti6Al4V after heat treatment

printed at the CNR, Institute of Chemistry of Condensed Materials and Technologies

for Energy, CNR ICMATE, Lecco site.

Figure 7: SLM samples in Ti6Al4V for pre-heat

treatment fatigue tests.

Figure 8: SLM samples in Ti6Al4V for post-heat

treatment fatigue tests.

Conclusions

Our experience, resulting from collaborations with our customers and different

universities, teaches us that vacuum is able to:

- minimize surface contamination at high heat treatment temperatures,

leading to a consequent improvement in the mechanical response of the component;

- make mechanical and corrosion verification tests, of the various printed

components, extremely repeatable;

- in some cases, clean up the samples surfaces, contaminated by printing

processes, making them shine, that, as we have already seen, take place

in a controlled atmosphere but not in total absence of oxygen.

In addition to these benefits there is also the fact that the materials mentioned

above are mostly used for aerospace and medical applications, in which very strict

rules must be respected to reduce surface contamination and to maximize mechanical

properties.

For what has been presented so far, the vacuum heat treatment turns out to be

a mandatory post process step when specific components and materials processed with

SLM technology are taken into consideration.

Do you like this blog?

For us your opinion matters, so we would be very pleased if you could write a review about us or our blog.