As discussed in the

previous part

of the article we will pass through benefits and drawbacks of Binder

Jetting (BJ) and Metal Injection Moulding (MIM) technologies.

I think you’ll be surprised by some of the information I’m going

to reveal, read on.

To analyze in detail the pros and cons of binder jetting, it has to be considered

that this technology is inspired by a wider category of additive manufacturing

technologies defined as Material Jetting.

A glance at Material Jetting

Basically, in Material Jetting technologies, all the part material is dispensed

from a print head.

Instead, in the Binder Jetting technology, a binder or other additive

is printed onto a powder bed which forms the bulk of the parts.

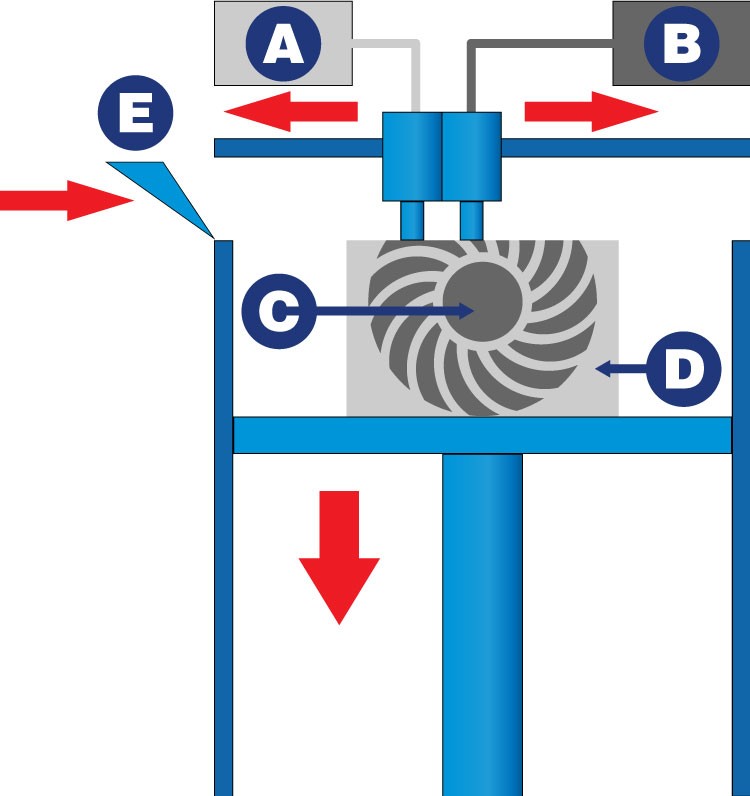

A: support material; B: build material; C: part; D: part support; E: leveling blade

To get a complete picture of the advantages and disadvantages of binder jetting,

we have to first analyze pros and cons of material jetting and see how the benefits

and drawbacks of binder jetting fit into this context.

The primary advantages of material jetting include

- low cost,

- high speed,

- scalability,

- ease of building parts in multiple materials.

Material jetting machines are much lower in cost than other AM machines,

particularly the ones that use lasers.

In general, these machines can be assembled from standard components, while other

machines have many more machine-specific components.

High speed and scalability are related: by using print heads with hundreds or thousands

of nozzles, it is possible to deposit a lot of material quickly and over a considerable

area. Scalability in this context means that printing speed can be increased by

adding another print head to a machine, a relatively easy task, much easier than

adding another laser to Selective Laser Melting or Selective

Laser Sintering machines.

For completeness, I will show you a few disadvantages of Material Jetting, just

to provide a more balanced presentation.

- The choice of materials to date is limited, only waxes

and photopolymers are commercially available.

- Part accuracy, particularly for large parts, is generally

not as good as with some other processes, notably vat photopolymerization and

material extrusion. However, accuracies have been improving across the industry

and are expected to improve among all processes.

Let's now go into detail of the binder jetting manufacturing process.

Did you like this article up to here?

Before you continue, follow us on our LinkedIn page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

Binder Jetting pros and cons

The binder jetting process shares many of the advantages of material jetting

relative to other additive manufacturing processes.

With respect to MJ, binder jetting has some distinct advantages.

- It can be faster since only a small fraction of the total

part volume must be dispensed through the print heads.

However, the need to distribute powder adds an extra step, slowing down binder

processes somewhat.

- The combination of powder materials and additives in binders enables

material compositions that are not possible, or not easily

achieved, using direct methods.

- Slurries with higher solids loadings are possible with

BJ, compared with MJ, enabling better quality ceramic and metal parts to be

produced.

- Binder jetting processes lend themselves readily to printing colors

onto parts.

As a general rule, however, parts fabricated using BJ processes tend to have

poorer accuracies and surface finishes than parts made with MJ. Infiltration steps

are typically needed to fabricate dense parts or to ensure good mechanical properties.

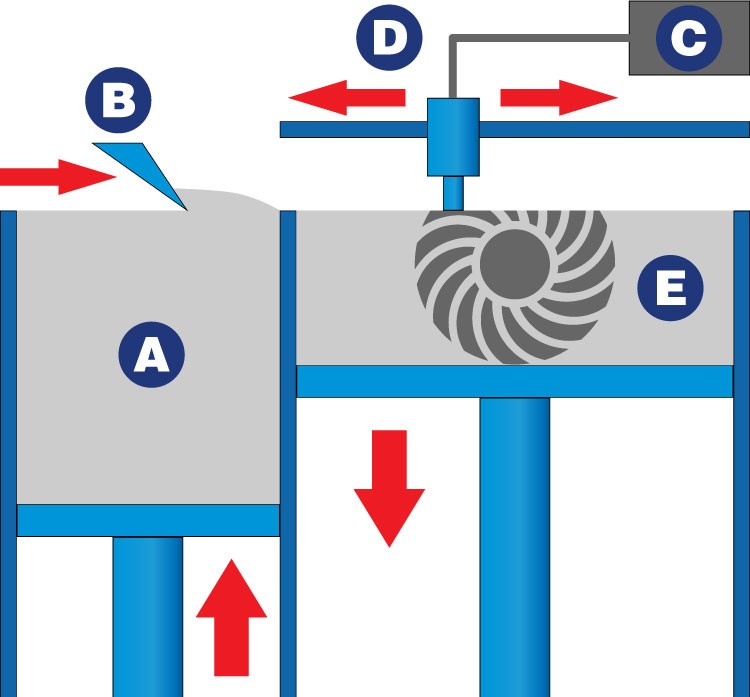

A: metal powder stock; B: squeegee; C: binder; D: print head; E: powder bed

As with any set of manufacturing processes, the choice of the process and material

depends largely on the requirements of the part or device.

It is a matter of compromising on the best match between process capabilities and

design requirements.

Is binder jetting going to replace metal injection molding?

Read the next chapter to have the right answer.

Metal Injection Moulding pros and cons

Now it’s the turn of Metal Injection Moulding: what makes your part suitable

for creation via MIM?

To determine this, here's a look at some of the advantages of this process:

- Design Complexity: if you're satisfied with the design

freedom you get from plastic injection molding but want to

craft metal parts, then MIM could be right for you. That's because the two processes

are quite similar in terms of design complexity - the main differences being

that one produces plastic parts and the other metal ones. With MIM, cross holes,

angle holes, splines, undercuts, side holes and grooves are all possible. Additionally,

with MIM you can create whole parts that would often have to be created separately

and assembled in post-production.

- Small Size: MIM uses very fine powders to create fully

dense metal parts, hence the process is best for small parts, typically those

that weigh between 0.1 and 250 grams.

- Production Volume: MIM can be a very cost-effective

process, but only if the right number of parts are needed. Typically, the cost

benefits are most noticeable and most worth it when part runs are between 10,000

and 20,000. The potential cost savings from using MIM might not be evident at

all producing fewer than 10,000 items.

- Properties: as we've already noted, if the process

is carried out correctly MIM can create fully dense or near fully dense metal

parts when the process is complete. It's particularly beneficial for parts that

are too small or too detailed to machine out of bar stock. For comparison's

sake, it's estimated that the part density is 98% via MIM, compared to 100%

via conventional machining processes.

- Economical: unlike machining, MIM doesn't cut away

existing metal - it uses only the amount of materials that is necessary to create

the product. Nothing is wasted.

Conclusions

After presenting in detail the pros and cons of the Binder Jetting vs. Metal

Injection Molding technologies, we can conclude that BJ is not destined to replace

the MIM in a short time.

Today binder jetting is a more convenient technology when it comes to small productions

at the prototype level of components with complex geometry. In this case the MIM

should face a design and production of always different molds that would result

in an unjustified increase in the final price of the single component.

On the other hand, metal injection molding is a much cheaper technology when

it comes to greater productions of a component even with complex geometry and reduced

dimensions. In this case the cost of the single mold can be amortized during the

repeated production of the same component and it turns out to be a more productive

technology.

To get rid of any doubt, take a look at the final comparison table:

|

Metal Injection Molding |

Binder Jetting |

| Cost |

Cheaper when producing many parts. |

Cheaper when producing few parts. |

| Accuracy |

Today the best choice in term of design complexity, especially for

small parts. |

The technology is getting better every day and it’s expected to

highly improve. |

| Speed |

Lower speed if we consider the entire process chain (design and

production of moulds). |

Higher speed if we consider the entire process chain. |

| Density |

It's particularly beneficial for parts that are too small or too

detailed to machine out of bar stock. |

Infiltration steps are typically needed to fabricate dense parts

or to ensure good mechanical properties. |

| Productivity |

The cost benefits are most noticeable and most worth it when part

runs are between 10,000 and 20,000. |

More convenient when it comes to small productions at the prototype

level. |

Do you like this blog?

For us your opinion matters, so we would be very pleased if you could write a review about us or our blog.