In the first

part of the article we’ve seen how AlTiN thin film deposition process was carried

out via reactive Physical Vapor Deposition High-Power Impulse Magnetron

Sputtering (PVD HiPIMS) to coat Ti6Al4V substrates, realized via

Selective Laser Melting (SLM).

Two different SLM process conditions were employed for modifying the obtained part

surface morphology and, later, the samples were heat-treated under high

vacuum.

Now it’s time to proceed with the analysis of the data acquired during the experimental

phase. Do not miss this in-depth investigation and the conclusions at the end, we’ll

provide you all the information to get the most out of these three technologies.

Analysis of the Selective Laser Melting results

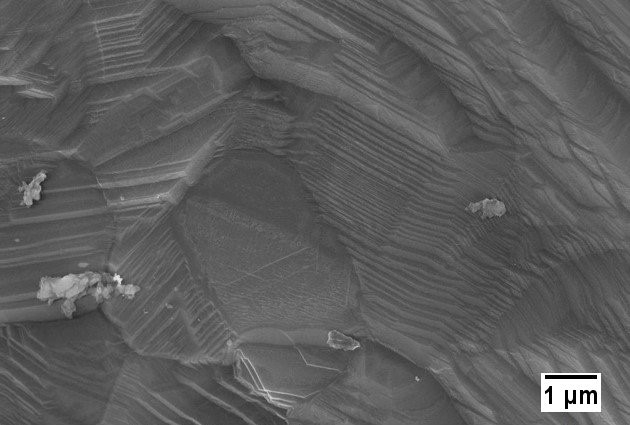

In the experimental phase we used two different scanning design to realize the

cylindrical samples. The upper surfaces of two Ti6Al4V substrates, manufactured

using the meander and contour scanning strategies, are shown in the following secondary

electron SEM images, respectively.

Whilst their topological features by three dimensional maps are listed in the

following figures, together with linear profiles concerning peculiar features of

the analyzed surfaces.

- Meander strategy: it is usually selected for manufacturing

massive parts.

- Contour strategy: it is employed for thin parts, like lattice

or trabecular structures, requiring more delicate energy deposition because

of their limited dimensions.

For these reasons, the two resulting morphologies are significantly different,

because the laser scanning paths and the corresponding values of density of power,

namely fluence, are largely modified in the two samples.

For both the samples, the direction of the laser scanning is well visible, which

can be directly associated to a preferential direction of melting, similar to a

welding process. In addition to this, adjacent laser tracks can be also seen, indicating

how the central part of the sample is processed at a certain powder layer.

The impact of the laser fluence

For pulsed wave lasers the fluence F can be calculated as follows:

\[F = {P \times t_{exp} \over d_p \times d_h \times s}\]

where P, texp, dp, dh

and s indicate laser power, exposition time, point distance, hatch distance

and layer thickness, respectively.

From the previous formula it can be calculated that the fluence increased from 35.5

J/mm3 up to 60 J/mm3 by changing the scanning strategy from

the contour to the meander one. This almost double increase of fluence can promote

the formation of larger liquid pools, inducing smoother surface of the liquid material

during its solidification. Moreover, it is also visible from the 3D maps that the

use of the contour strategy is not able to melt all the powders,

due to the lower density of energy irradiated to the single layer. As a result,

some residual powders can be found not completely melted but partially joined to

the upper surface and the irregular surface possessed high roughness (Sa=13.3 µm).

On the contrary, the meander scanning strategy led to a more regular topology

with lower roughness (Sa=4.2 µm) and without prominent asperities and seemed

to be more suitable to be coated by a PVD process.

Therefore, the contour strategy resulted inapt to be efficiently coated by a

protective layer without any deep modification, rather due to the presence of pronounced

valley and hills. Even in case of a polished surface, the residual porosity could

remain a critical issue.

For this reason, in this work only meander selective laser melted samples were

taken into account to the coating process.

Analysis of the heat-treating results

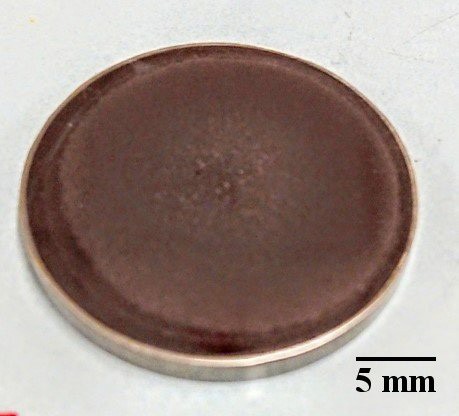

In the following figure you can evaluate how a 1-hour vacuum thermal treatment

at 950°C, into a TAV all metal vacuum furnace, gave rise to a dramatic

changing of selective laser melted samples.

After that titanium-aluminum-nitride coatings were deposited

onto such kind of treated substrates in order to evaluate their properties.

In order to characterize the coated samples by nanoindentation, the substrate surfaces

were polished to almost a mirror like finishing. This process, moreover, led to

exclude the influence of the several peculiar surface morphologies.

Analysis of the coating results

During reactive sputtering process, N2 partial pressure affects the

deposition rate in addition to the nitrogen content present in the growing film.

In particular, a high rate leads to a coating with high internal stresses, which

can be detrimental for its mechanical stability.

Indeed, a nitrogen partial pressure of 14% gave rise to a film (deposited onto Si)

which spalled completely, whilst 20, 25, and 30% permitted to obtain mechanically

stable coatings with sputtering rate of 2.3, 2.2 and 1.5 µm h-1, respectively.

Energy dispersive X-Ray spectroscopy quantitative analysis confirmed the stoichiometry

of Al0.5Ti0.5N1.0, highlighting that the three

partial pressures did not affect the material composition.

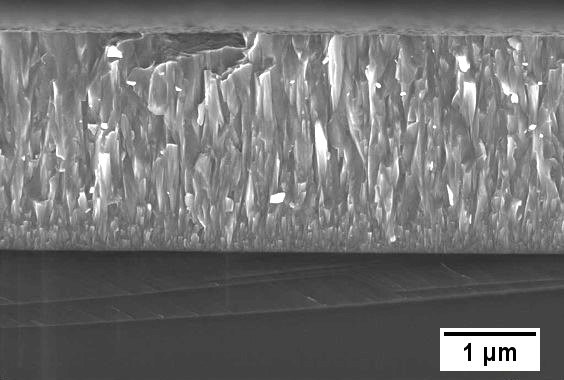

The following figure shows a secondary electron micrograph of the film cross-section

where it is possible to observe the typical PVD columnar dense morphology of the

obtained films.

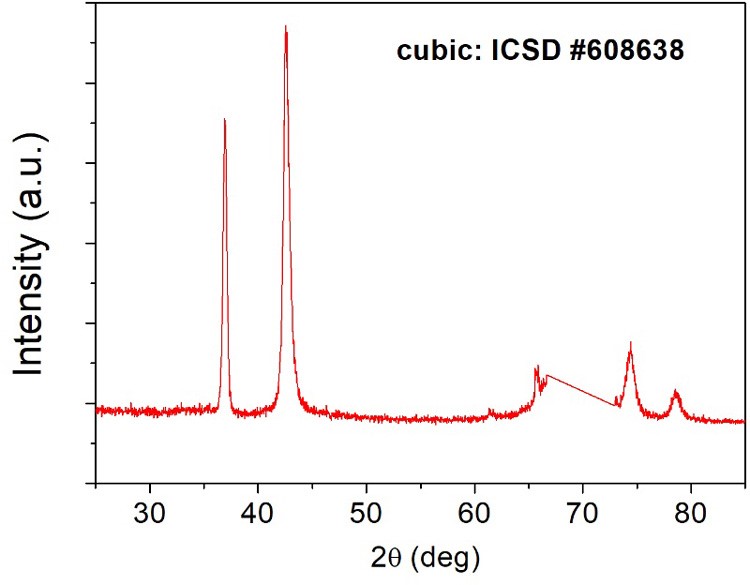

The following chart reports the X-Rays diffraction profile of the AlTiN film,

which can be attributed to a cubic phase (note that the peak of the substrate present

between 65° and 74° was removed).

The coating deposited onto polished commercial Ti6Al4V samples resulted having

a quite different behavior from those deposited onto Si.

Did you like this article up to here?

Before you continue, follow us on our LinkedIn page pressing the button here below!

In this way, we'll be able to keep you updated on most advanced technologies for heat treatments not only with our posts, but also with the best articles that we collect around the web.

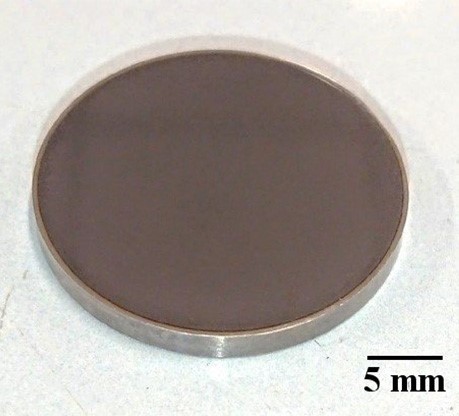

The adhesion of the coating

The following photo shows how only the films deposited with pN2 of

25% demonstrated to have a satisfactory adhesion to the substrate of polished commercial

Ti64Al4V.

Whilst the films obtained with pN2 of 20 and 30% partially spalled

likely due to high internal stresses relaxation phenomena.

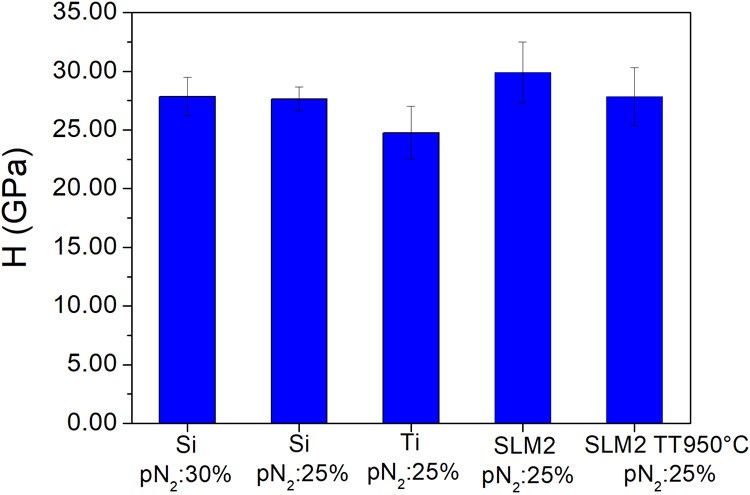

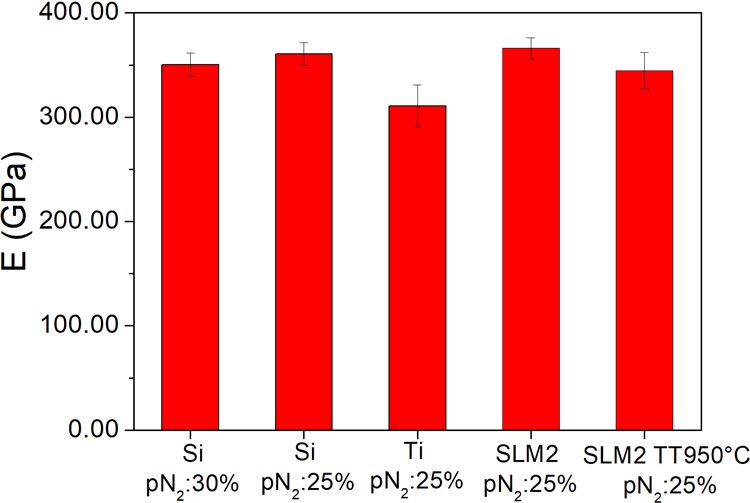

Hardness and elastic module of the coating

The following two graphs show the hardness and the elastic module of the deposited

AlTiN thin film, respectively.

Nanoindentation data indicate that the thin films deposited with pN2

of 25% and 30% exhibited very similar values of hardness H and elastic module E,

leading to conclude that N2 partial pressure did not affect significantly

the mechanical properties of the coatings.

Even though the film hardness values resulted slightly lower than the typical ones

of this kind of coating, the improvement of substrate surface features were remarkable,

if compared to the typical titanium alloy hardness (around 1 GPa).

The two rightmost bars refer to the selective laser melted substrate, prior and

after vacuum heat treatment respectively: in this cases values of H and E of the

thin film increased considerably. Note how the vacuum heat treatment seemed

to decrease those physical characteristics, likely due to a more relaxed

substrate microstructure, which reduce the entity of the film internal stresses.

Correlations between mechanical and tribological properties of the film

are very important for an assessment of its quality. Although hardness

is considered generally as the main property affecting wear resistance and load-carrying

capability of materials, properties such as toughness and elastic modulus are also

pivotal in describing the mechanical behavior of a coating.

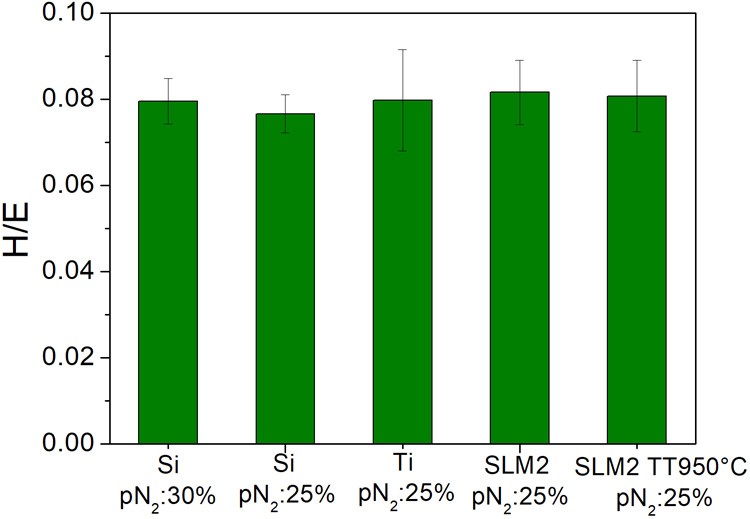

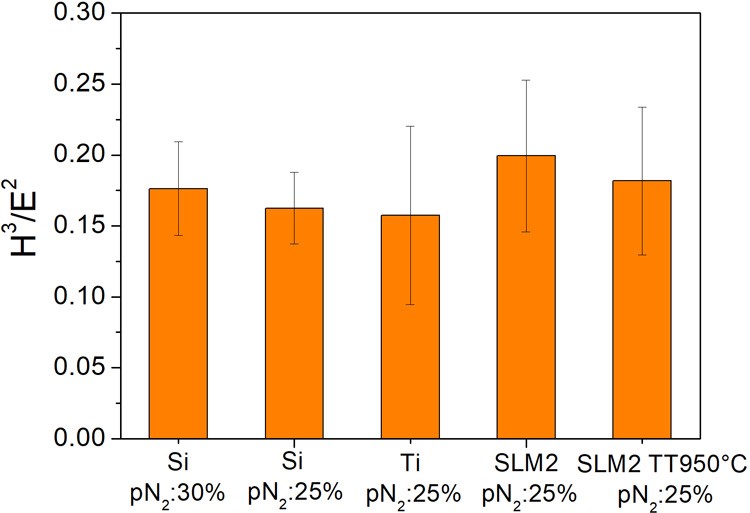

Let’s now examine nanoindentation data in terms of elastic strain to failure,

associated to H/E ratio, and resistance to plastic deformation H3/E2,

associated to the resistance to local contact load.

Elastic strain to failure and plastic deformation resistance of the coating

In the following two graphs, the ratios H/E (elastic strain to failure) and H3/E2

(plastic deformation resistance) suggested as the film deposited onto Ti6Al4V

selective laser melted substrate possessed better tribological behavior.

As described above, the thermal treatment modulated these properties slightly decreasing

them, even if the values remained within the errors.

Now we have to find an answer to one last question.

What happens if we try to coat a pristine surface?

Coating a pristine 3D printed surface

A pristine selective laser melted substrate was coated with AlTiN thin films

avoiding the polishing process, in order to evaluate the influence of the peculiar

morphology on the mechanical compatibility between the two materials.

The following two figures show a backscattered electron and secondary electron

SEM (Scanning Electron Microscopy) image respectively, showing the AlTiN coating

deposited onto pristine SLMed surface.

Unfortunately, how it is possible to observe, the coating spalled where the morphology

was particularly arcuate. In particular, the presence of a very thin film onto the

spalled zones (less bright gray areas in the first figure), confirmed that the spalling

process occurred during the deposition, and not later.

Conclusions

In this work, AlTiN hard coatings were deposited by reactive PVD HiPIMS with

the aim of improving the surface features of Ti6Al4V substrates, realized via Selective

Laser Melting.

Preliminary results demonstrated that it is possible to coat the titanium alloy

substrates with dense films with proper stoichiometry and crystallographic phase,

obtaining a good improvement of the mechanical surface features.

The laser scanning paths can modify significantly the surface morphology,

affecting the resulting adhesion of AlTiN coatings. In particular, between the meander

and contour scanning strategies, the first ones seemed to be more suitable to be

coated with the protective layer, when the surface is adequately treated by means

of polishing process.

The tribological properties of the resulting films showed a good behavior

of the couple film/substrate, even when the latter is vacuum thermal

treated. Unfortunately, the mechanical matching resulted not so

good in case of coating onto a pristine surface. Indeed, the surface morphology

gave rise to coating spalling where the roughness is particularly marked. In future,

further investigations will be mainly addressed to work on the substrate morphology

as well as the deposition coating conditions, in order to prevent those kinds of

detrimental phenomena.

National Research Council; Institute of Condensed Matter Chemistry and Technologies

for Energy (Padova): S. Battiston, F. Montagner, V. Zin

National Research

Council; Institute of Condensed Matter Chemistry and Technologies for Energy

(Lecco): C.A. Biffi, J. Fiocchi, A. Tuissi

TAV VACUUM FURNACES SpA: A. Fiorese, A. Gionda

Do you like this blog?

For us your opinion matters, so we would be very pleased if you could write a review about us or our blog.